We hope to give you a small impression about our products.

Please feel comfortable at any time to contact us or our representatives closed to you for any further information. Our engineers have many years of experience in high voltage business and will do their best to be at your service and help you, to realize your projects. We would like to create a long term relationship with you based on trust and reliability. We do want to support you with all our possibilities and ideas with many years of experience.

In 2015 we did begin with the research of higher quality composites. This became necessary to shift the physical limits and to add another degree of freedom in design for a new generation of HV equipment. Since than we did constantly invest into an own fibreglass manufacturing and are now able to produce tubes and plates with extraordinary mechanical as well as electrical properties. Our best quality, which requires longer manufacturing times can be guaranteed as PD-free.

At our manufacturing facility we process raw material by CNC-milling, lathing or welding into its shape.

As a rough idea we can manufacture entire composite plates up to approx. 12m length by 2m width with up to approx. 50mm thickness, where it is possible to CNC these enormous plates directly in our workshop (for now CNC milling is only possible up to a width of max. 1.65m, but over the full length of 12m). As application they can be used as PD-free plates in HV-applications, but also they are soon getting the approval to be used in the anti ballistic sector. PD-free fibreglass tubes can be manufactured up to diameters of approx. 500mm and length up to 6m, 8m or 12m, depending on diameter and wall-thickness. Own vacuum-processes with high reliability guarantee constant quality especially at capacitors and resistors, which are the primary components.

All main components are manufactured in house, as only like this we can insure the constant high quality.

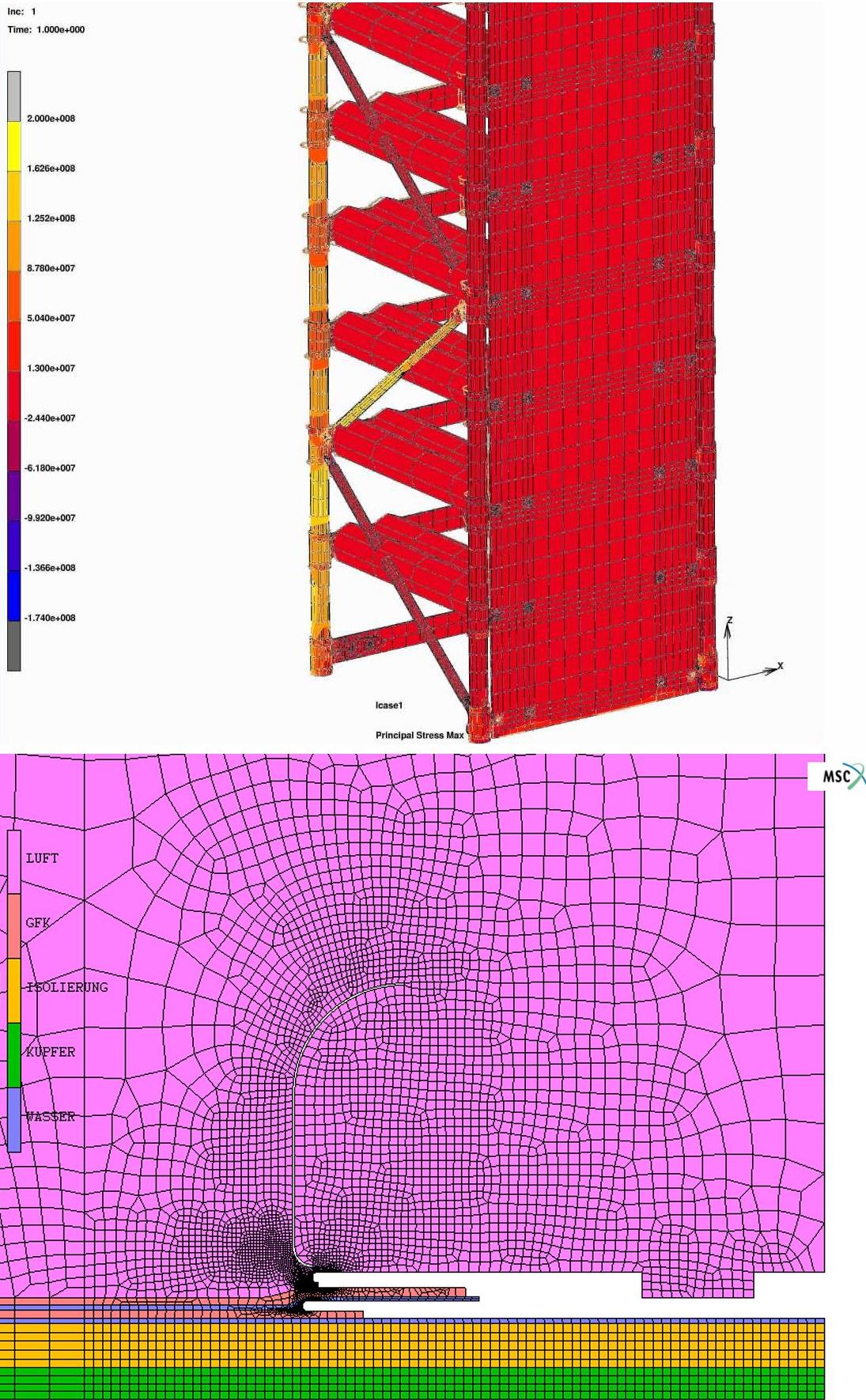

As some of our strengths we might mention, that we can simulate our parts and structures with FEM (finite element method) and also in more uneven cases even with CFD (computational fluid dynamics). FEM is used to calculate and optimize the mechanical structure, e.g. for earth quake simulations, or just simple material optimisation. The multiphysics capability or or FEM code allows us as well, to calculate precisely the electrical field distribution to optimize the geometry of the parts or even complete machines.